CITYJET

EXCEEDING ALL YOUR EXPECTATIONS IN DESIGN, PERFORMANCE, USER FRIENDLINESS AND RELIABILITY

SPECIFICATIONS

| Diameter: | 100 - 450mm |

|---|---|

| Max length: | 120m |

| Water Tank: | 600 |

| Motor: | Diesel |

| Max Bar: | 200 bar |

| Liters: | 60 lt |

| Nozzles: | 2 |

| Dimensions: | 130 Χ 125 Χ 120 cm |

| Weight: | 620 kg |

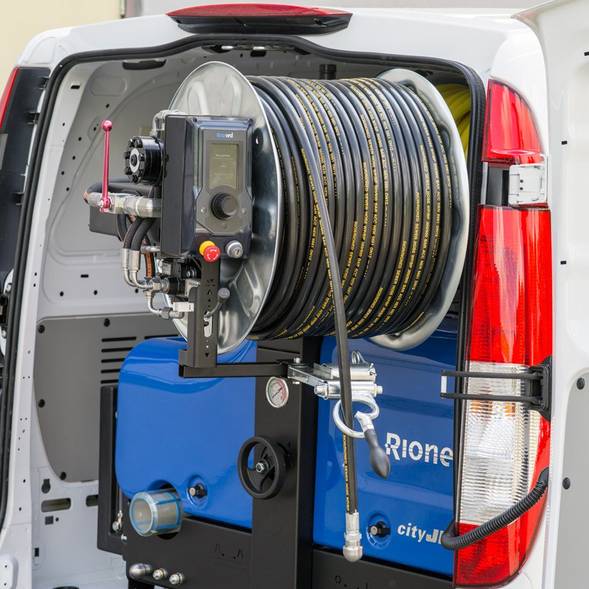

Rioned® NEW CityJet high pressure skid mounted jetting machine

for house connexions, sewer pipes, grease and drainage pipes up to a maximum diameter of 300 mm.

The NEW CityJet sets the latest standard in the design and technology of compact build diesel powered high pressure machines:

• a new 135° pivoting high pressure hose reel offers the operator a convenient and ergonomic way of working

• the new „Compact System®"- water tanks with 2 x 300L lead to an extreme compact machine with build in depth of less then 1,3 meter. The specific design of the tanks improve the driving qualities of the van

• a new developed water cooling and exhaust system ensure a better controlled temperature inside the van and damp the noise even more

• very advanced and modern design without making any restrictions to the objective of being a powerful cleaning machine.

ENGINE (capacity-dependant)

Kubota water cooled 4 cylinder in line – diesel engine, max. power 22 kW (30 HP) at 3.000 RPM. Complete with ignition key, hour counter, 30 L petrol tank, battery (12 volt electric system) and several warning/control lights. Standard an overheating protection is build up. Average consumption 190 gr/hp-hour.

All engines have the by Kubota patented TVCS (Three Vortex Combustion System) and meet the euro 3 norm.

Engine cooling system by means of a corrosion proof heat exchanger which is build between the water filter and the HP pump. A temperature safety switch shuts down the engine if the temperature in the water tank gets over 55 degrees. Furthermore an expansion tank is build up for the cooling liquid of the engine. The level and the temperature of this cooling liquid are also being controlled and the engine is stopped when the values are exceeded.

Exhaust pipe delivered including a special stainless (inox) protection cover.

HP-PUMP (Capacity-dependant)

HP-pump, Typ Speck / Rioned P45 with capacity 200 bar at 50 Lpm. Complete with automatic pressure regulator ULH262 with by-pass, water filter 1¼”, manometer and connection to the high pressure hose reel, HP-pump and water filter. All HP-hoses, intermediate hoses and couplings have a sufficient diameter and when possible radius bends instead of couplings are being used.

The 3-cylinder plunger pumps have a crankcase of solid sphero-cast-iron, which ensure stability and vibration dampening and have Bronze valve casings. The crankshaft and taper roller bearings together with plain bearing con rod all run in oil.

Plungers with double plunger sealing and all gaskets in seal sleeves ensuring precise centering and easy replacement. The suction and discharge valves are identical and easily accessible. The pump has an automatic lubrication by means of the oil filling.

Materials used:

Valve casing: Bronze.

Plungers: Solid ceramic

Valves: Duplex steel

Sleeves: Nitrile with fabric reinforcing

Crankshaft: Drop-forged and case-hardened

On the engine and pump axles v-belt pulley are being build up, not less then 4 high quality v-belts drive the pump with a maximum of 1.000 RPM. (depending on the capacity) The complete drive is protected by an aluminium cover according CE legislation.

HP-HOSE REEL

New developed pivoting HP-hose reel made out of pressed stainless steel. Diameter 530 mm, width 350 mm.

Hydraulic drive by means of a 4cc hydraulic pump with a direct connection to the diesel engine. The hydraulic engine drives the hose reel by means of a dental wheel construction (ratio 1:3) which requires less maintenance. It is speed adjustable by it’s control lever. At full throttle not less than 12 L oil is used to drive the hose reel.

Standard ½ HP-ball valves and 80M NW13 Rioned High pressure hose are being build up. Also radius bends to reduce the pressure lost in the system to a minimum.

The hose reel is build at an ergonomic working height, conform CE and ARBO legislation.

The hose reel itself, together with the control box and hydraulic control lever can be pivoted in each position over 135º, to obtain the optimum working condition.

A hose guidance which can turn over 360º with an open eye construction enables the precise working even at the hardest conditions. By this special construction the HP hose to be rolled off by hand and later be rolled back on again by use of that hose guidance..

FILLING HOSE REEL

Hand operated filling hose reel from cast aluminum which contains 50M ¾”(NW19) filling hose. The single side hanging makes this filling hose reel extra compact (ø 450 mm, length 280 mm). It is placed beside the HP hose reel, directly on the front side of the machine. Beneath these hose reels there are the moulded fibreglass water collection plates.

WATERTANKS

2 Compact System® - water tanks with a total volume of 600 l (2 x 300 l). Both of them are foreseen with all needed connections and have manholes on top. They are inter connected by a connection hose of a sufficient diameter to ensure both of them being filled or emptied at the same time.

The tanks are produced of black Poly-ethylene (PE) to prevent alga growth as much as possible. They have an extreme compact size.

Dimensions: H: 1200 X W: 620 X L: 490

They have a very low centre of gravity because they will be build directly on the bottom of the vehicle. Perfect support by means of the double steel belt in the special belt grooves.

2 special shaped water tanks instead of 1; in this way there is a natural water braker (anti swing plate) which minimize the movement of liquid while the vehicle is mobile.

FRAME

The complete machine is build in frame made out of welded and screwed U-steel bars, ready to build inside a suitable van.

The engine and high pressure pump are build up on a sub frame which is mounted to the main frame by means of rubber shock absorbers.

The main frame is being undercoated with an etching primer layer and catalytic primer before they are powder coated. Standard the colors are black frame and blue hose reel arm.

The transparent PVC water filter is build up on the front side where it is easy reachable and always in sight. The water filter is connected between the filling from the water tank to the HP pump with an extra valve between water tanks and filter.

The fiberglass covers protect the engine and pump, reduce the noise and collect the water from the hose reels. Furthermore there are 2 support legs build underneath which also allow a lift truck to lift the machine. (easy build in)

OPERATION

The complete operation of this machine is controlled from the control box which is build besides the pivoting HP hose reel. There are several control lights, ignition key (or button) hour counter, throttle control (buttons) and an emergency button being build up.

A 12 Volt plug is build up on the switch box which is build on the front side of the water tanks.

The hydraulics are controlled from underneath the control box, besides the pivoting HP hose reel.

ACCESSORIES

2 standard jetting nozzles (1/2”)

1 pistol with jetting lance 850 mm and flat spray nozzle

2 wrenches

1 complete users manual according to the latest CE-specifications.

DIMENSIONS / WEIGHT

Length ca. 1.800 mm (with 4 water tanks)

Width: ca. 1.250 mm

Height: ca. 1.200 mm

Weight: as of 620 Kg

ARE YOU INTERESTED?

Υoy can call us at +30 210 882 7770 or alternatively you cancomplete the follwing form:

Rioned® NEW CityJet high pressure skid mounted jetting machine

for house connexions, sewer pipes, grease and drainage pipes up to a maximum diameter of 300 mm.

The NEW CityJet sets the latest standard in the design and technology of compact build diesel powered high pressure machines:

• a new 135° pivoting high pressure hose reel offers the operator a convenient and ergonomic way of working

• the new „Compact System®"- water tanks with 2 x 300L lead to an extreme compact machine with build in depth of less then 1,3 meter. The specific design of the tanks improve the driving qualities of the van

• a new developed water cooling and exhaust system ensure a better controlled temperature inside the van and damp the noise even more

• very advanced and modern design without making any restrictions to the objective of being a powerful cleaning machine.

ENGINE (capacity-dependant)

Kubota water cooled 4 cylinder in line – diesel engine, max. power 22 kW (30 HP) at 3.000 RPM. Complete with ignition key, hour counter, 30 L petrol tank, battery (12 volt electric system) and several warning/control lights. Standard an overheating protection is build up. Average consumption 190 gr/hp-hour.

All engines have the by Kubota patented TVCS (Three Vortex Combustion System) and meet the euro 3 norm.

Engine cooling system by means of a corrosion proof heat exchanger which is build between the water filter and the HP pump. A temperature safety switch shuts down the engine if the temperature in the water tank gets over 55 degrees. Furthermore an expansion tank is build up for the cooling liquid of the engine. The level and the temperature of this cooling liquid are also being controlled and the engine is stopped when the values are exceeded.

Exhaust pipe delivered including a special stainless (inox) protection cover.

HP-PUMP (Capacity-dependant)

HP-pump, Typ Speck / Rioned P45 with capacity 200 bar at 50 Lpm. Complete with automatic pressure regulator ULH262 with by-pass, water filter 1¼”, manometer and connection to the high pressure hose reel, HP-pump and water filter. All HP-hoses, intermediate hoses and couplings have a sufficient diameter and when possible radius bends instead of couplings are being used.

The 3-cylinder plunger pumps have a crankcase of solid sphero-cast-iron, which ensure stability and vibration dampening and have Bronze valve casings. The crankshaft and taper roller bearings together with plain bearing con rod all run in oil.

Plungers with double plunger sealing and all gaskets in seal sleeves ensuring precise centering and easy replacement. The suction and discharge valves are identical and easily accessible. The pump has an automatic lubrication by means of the oil filling.

Materials used:

Valve casing: Bronze.

Plungers: Solid ceramic

Valves: Duplex steel

Sleeves: Nitrile with fabric reinforcing

Crankshaft: Drop-forged and case-hardened

On the engine and pump axles v-belt pulley are being build up, not less then 4 high quality v-belts drive the pump with a maximum of 1.000 RPM. (depending on the capacity) The complete drive is protected by an aluminium cover according CE legislation.

HP-HOSE REEL

New developed pivoting HP-hose reel made out of pressed stainless steel. Diameter 530 mm, width 350 mm.

Hydraulic drive by means of a 4cc hydraulic pump with a direct connection to the diesel engine. The hydraulic engine drives the hose reel by means of a dental wheel construction (ratio 1:3) which requires less maintenance. It is speed adjustable by it’s control lever. At full throttle not less than 12 L oil is used to drive the hose reel.

Standard ½ HP-ball valves and 80M NW13 Rioned High pressure hose are being build up. Also radius bends to reduce the pressure lost in the system to a minimum.

The hose reel is build at an ergonomic working height, conform CE and ARBO legislation.

The hose reel itself, together with the control box and hydraulic control lever can be pivoted in each position over 135º, to obtain the optimum working condition.

A hose guidance which can turn over 360º with an open eye construction enables the precise working even at the hardest conditions. By this special construction the HP hose to be rolled off by hand and later be rolled back on again by use of that hose guidance..

FILLING HOSE REEL

Hand operated filling hose reel from cast aluminum which contains 50M ¾”(NW19) filling hose. The single side hanging makes this filling hose reel extra compact (ø 450 mm, length 280 mm). It is placed beside the HP hose reel, directly on the front side of the machine. Beneath these hose reels there are the moulded fibreglass water collection plates.

WATERTANKS

2 Compact System® - water tanks with a total volume of 600 l (2 x 300 l). Both of them are foreseen with all needed connections and have manholes on top. They are inter connected by a connection hose of a sufficient diameter to ensure both of them being filled or emptied at the same time.

The tanks are produced of black Poly-ethylene (PE) to prevent alga growth as much as possible. They have an extreme compact size.

Dimensions: H: 1200 X W: 620 X L: 490

They have a very low centre of gravity because they will be build directly on the bottom of the vehicle. Perfect support by means of the double steel belt in the special belt grooves.

2 special shaped water tanks instead of 1; in this way there is a natural water braker (anti swing plate) which minimize the movement of liquid while the vehicle is mobile.

FRAME

The complete machine is build in frame made out of welded and screwed U-steel bars, ready to build inside a suitable van.

The engine and high pressure pump are build up on a sub frame which is mounted to the main frame by means of rubber shock absorbers.

The main frame is being undercoated with an etching primer layer and catalytic primer before they are powder coated. Standard the colors are black frame and blue hose reel arm.

The transparent PVC water filter is build up on the front side where it is easy reachable and always in sight. The water filter is connected between the filling from the water tank to the HP pump with an extra valve between water tanks and filter.

The fiberglass covers protect the engine and pump, reduce the noise and collect the water from the hose reels. Furthermore there are 2 support legs build underneath which also allow a lift truck to lift the machine. (easy build in)

OPERATION

The complete operation of this machine is controlled from the control box which is build besides the pivoting HP hose reel. There are several control lights, ignition key (or button) hour counter, throttle control (buttons) and an emergency button being build up.

A 12 Volt plug is build up on the switch box which is build on the front side of the water tanks.

The hydraulics are controlled from underneath the control box, besides the pivoting HP hose reel.

ACCESSORIES

2 standard jetting nozzles (1/2”)

1 pistol with jetting lance 850 mm and flat spray nozzle

2 wrenches

1 complete users manual according to the latest CE-specifications.

DIMENSIONS / WEIGHT

Length ca. 1.800 mm (with 4 water tanks)

Width: ca. 1.250 mm

Height: ca. 1.200 mm

Weight: as of 620 Kg

APPLICATION

SECTORS

ACCESSORIES & SUPPLIES

RIONED High Pressure Nozzles

The Rioned Maxi root cutter is suitable for larger high pressure jetting machines and combination un...more